Volumetric pump test bench

Irrigation pumps

and for spraying

High pressure washer pumps

Piston pumps

Diaphragm pumps

Pressure washers

Our test bench for positive displacement water piston pumps offers high-level features:

Testing of pumps with and without internal pressure regulator

Maximum pump power: 30 KW

Variable speed from 500 to 1900 RPM

Maximum flow rate 24 mc/h

Delivery pressure regulation from 0 to 100 bar with automatic valve

Suction vacuum regulation with automatic valve

2 m³ stainless steel tank

Axle height positioning system with quick coupling

Oil inlet and suction system during test

Quick-release couplings for male gas threads

Noise and accident protection

Computers and software for control, data acquisition and printing bulletins

The mechanical structure includes a painted iron base with pump-motor alignment system, height-adjustable sliding table, and aluminium and Lexan guards for safety and soundproofing. The drive motor is powered by alternating current with an output of 25 kW. The hydraulic system includes a 2 m3 stainless steel tank and piping with proportional valves to regulate pressure.

The flow rate is measured by flow meters with 0.5% accuracy, while the pressure is monitored by specific transducers. The oil inlet and suction system is managed by a dedicated pump.

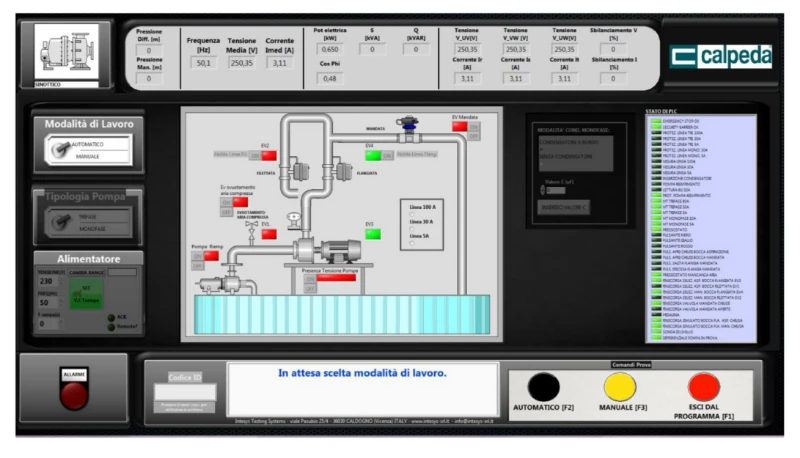

It is controlled by a PLC and a computer with dedicated software, which allows database management, user interface, graphics, tables and reports. Also included in the scope of delivery are a synoptic and grid charts showing the pump’s behaviour under different conditions.

PumpTest Software

Our control and data acquisition software, developed in LabVIEW, efficiently manages the setup and analysis of test bench data. The manual test cycle involves the PC-controlled manual acquisition of data such as pressure, power, electric current and DC voltage. The operator controls the valves and servomechanisms during the test, ensuring complete supervision.

The automatic test cycle, based on preset data in the pump database, automatically adjusts valves and servomechanisms according to the selected pump code. The valve positions itself in a predefined manner, allowing accurate verification of data against sample values with programmable tolerances.

On-screen visualisation and data storage provide a detailed overview of performance during the test, with clear warnings of compliance or non-compliance. The database stores pump specifications and tolerances.

The reports generated include standard test bulletins, highlighting measured values and deviations from sample values. Wherever possible, range-prevalence graphs are included, providing a visual representation of the results. The software adapts to ISO 9906 standards, offering a comprehensive and efficient approach to pump test data management.

Discover more about PumpTest

INTESYS Srl

Sistemi di collaudo

Viale Pasubio, 25/4 – 36030

Caldogno (Vicenza)

tel: 0444 905440

fax 0444 1830 932

info@intesys-srl.it